The two Swedish renowned organizations, cable support systems company Wibe Group and mining and smelting company Boliden have entered a partnership where Wibe Group will utilize Boliden's Low-carbon Zinc, known for having one of the world’s lowest CO2 footprints among refined zinc products. The agreement is another step in Wibe Group’s ambition to lead the industry transformation, aiming for a low-carbon society.

"As we embrace the urgency of Europe’s green transition, Wibe Group and Boliden takes the lead in promoting sustainable metals. Boliden’s Green Transition Metals offer some of the most sustainable solutions available today, laying the foundation for the climate transition. We encourage our partners and clients to join us in this industry-wide shift, reducing emissions and carbon footprints. So together with Wibe Group, we catalyze the transformation towards a greener and more sustainable future." Daniel Asplund, Zinc Sales Manager at Boliden says.

The agreement marks a vital step for Wibe Group as the green transition and working for a low-carbon society is at the core of the company strategy.

"As a major element in reducing our environmental footprint, we target transforming our raw materials. Making the shift to low-carbon zinc for our hot-dip galvanized products is not just a material change; it's a substantial positive influence on 40% of our entire product sales output. As Boliden, we're dedicated to advancing a low-carbon society, and Low-carbon Zinc serves as a significant and readily available element for this journey." Henrik Pedersen, Sales & Marketing Director at Wibe Group says.

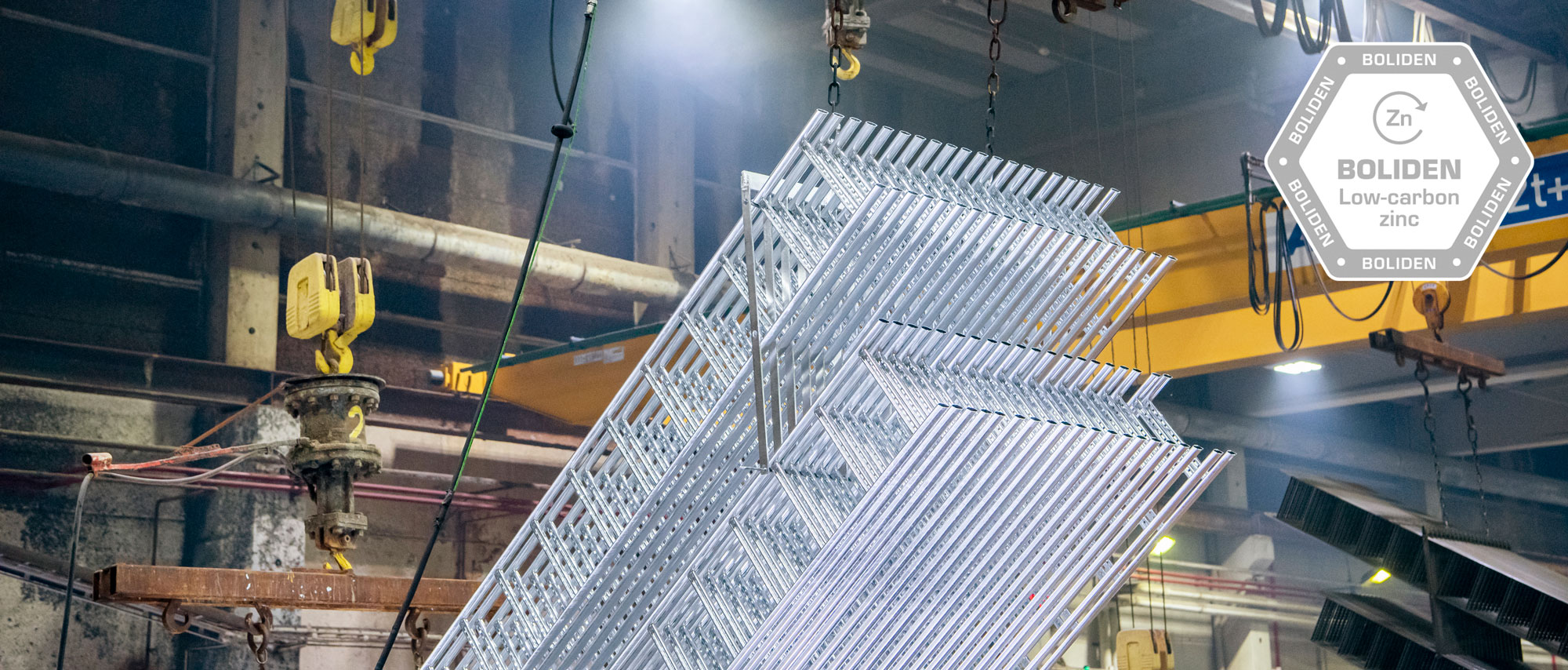

Zinc plays a vital role as a primary raw material in the production of galvanized steel. Galvanized steel is a steel product coated with a layer of zinc, which serves as a protective barrier, effectively shielding the steel from corrosion due to environmental factors. This zinc coating enhances the steel's durability and extends its overall lifespan. The result is a combination of steel's strength and versatility with the corrosion resistance provided by zinc.

Wibe Group has over 50 years of in-house expertise in hot dip galvanizing, leading to Wibe Group being one of the most renowned actors in the Nordics in the field of hot dip galvanizing. The ability to constantly improve processes and services gives Wibe Group a competitive advantage with high quality and high efficiency. This recent step is just the latest in a continuous strive to improve.

Boliden’s Low-carbon Zinc is mined in the company’s own mines, without using fossil energy. Smelters in Kokkola and Odda then produce the Low-Carbon Zinc that accounts for an emission of less than 1 ton of CO2 per ton of zinc2), compared to the industry average of 3.6 tons. This gives it one of the lowest CO2 footprints of any refined zinc in the world.

In 2024, Boliden will mark the inauguration of the smelter expansion project in Odda, a significant milestone in the company’s low-carbon journey. The expansion will elevate the annual production capacity from 200 ktonnes to 350 ktonnes, reinforcing Boliden’s commitment to sustainable zinc production.