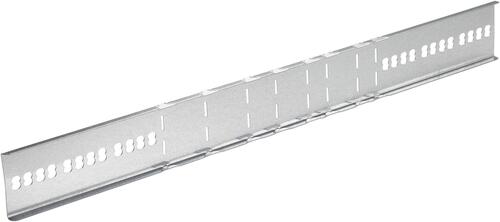

Cable tray coupling piece L=605

Item number

CSU0894000916

Local code:

*

GTIN:

8712186110481

Description:

Cable tray coupling piece L=605

Wibe Group. CSU0894000916 - Stago - stop end / reducer- 60x605 - steel - pre-galvanized - RAL9016

Properties

Status product

Product status

Commercialized

Commercial and Web

Short description

Cable tray coupling piece L=605

Medium description

Stago - stop end / reducer- 60x605 - steel - pre-galvanized - RAL9016

Material

Steel

Material type or surface treatment

Painted

Corrosion class

C2

Base

Activity

Cable support systems

Product family

Cable trays

Brand

Stago

GTIN

8712186110481

ETIM (EC002413-Connector for cable support system)

Model (EF000010)

Longitudinal joint

Hinged joint horizontal (EF006392)

No

Hinged joint vertical (EF006393)

No

Type of connection (EF000064)

Screw connector

Suitable for wire mesh tray (EF005163)

No

Suitable for cable ladder (EF005165)

No

Suitable for cable tray (EF005166)

Yes

Suitable for cable management system width (EF008339)

70-330 mm

Suitable for cable management system height (EF006391)

60 mm

Suitable for mesh cable tray filament (EF005164)

60-60 mm

Length (EF001438)

* mm

Suitable for circuit integrity (EF007806)

No

Material (EF002169)

Steel

Stainless steel, pickled (EF006388)

No

Material quality (EF001257)

Other

Surface protection (EF000139)

Continuously galvanized and coated

Colour (EF000007)

White

RAL (EF000116)

9016

Logistic

Weight pack 1

0.345 kg

Length pack 1

605 mm

Width pack 1

10 mm

Height pack 1

64 mm

Customs code

73089098

Net weight

0.35 kg

Certification

ETIM class

EC002413

Environmental

GWP Total A1-A3

1.383 kgCO2e

Product downloads

Environmental Documents

| Corrosion class | C1 | C2 | C3 | C4 | C5 | CX | |

| Environmental corrosion | Very low | Low | Average | High | Very high | Extreme | |

| Examples of environments | Indoors | Heated areas with arid atmosphere and insignificant quantities of pollutant, e.g. offices, shops, schools and hotels. | Non-heated areas with fluctuating levels of temperature and humidity. Few instances of condensation and low levels of airborne pollution, e.g. sports halls and warehouses. | Average levels of humidity and some airborne pollution resulting from production processes, e.g. breweries, dairies, laundries. | High humidity and considerable airborne pollution as the result of production processes, e.g. chemical plants, swimming pools and dockyards. | Buildings with almost permanent condensation and with high pollution | Industrial buildings with extreme humidity and aggressive atmosphere. |

| Outdoors | Atmospheres with low levels of airborne pollution. Rural areas. | Atmospheres containing some salt or average levels of air-borne pollution. Urban and light industrial areas. Areas affected by coastal conditions. | Atmospheres with average salt content or discernible levels of airborne pollution. Industrial and coastal areas. | Industrial areas with high humidity and aggressive atmosphere, and coastal areas with high salinity | Offshore areas with high salinity, industrial areas with extreme humidity, and aggressive atmospheres, sub-tropical or tropical atmospheres. | ||

|

Wibe Group designation

Exceeds requirements. Extremely high durability.

Recommended very high durability ( >20 years)

Possible alternative. High durability (10-20 years) |

Electro-galvanized (EG) |

|

|

||||

| Pre-galvanized (PG) |

|

|

|

||||

| Zinc+ (Z+) |

|

|

|

|

|||

| Hot-dip galvanized (HDG) |

|

|

|

|

|

||

| Zinkpox (ZP) |

|

|

|

|

|

|

|

| Stainless steel AISI 304L(SS304) |

|

|

|

|

|

|

|

| Stainless steel AISI 316L (SS316) |

|

|

|

|

|

|

|

| Glass Fibre Reinforced Polymer (FRP/GRP) |

|

|

|

|

|

|

|

This table shows estimated values.

For more detailed advice, please contact technical support at Wibe Group