Mita Flex - FRP/GRP cable support for harsh environments

Wibe Group presents Mita Flex FRP/GRP Cable Management Solution

Mita Flex is produced in FRP/GRP, a material perfectly suited to be installed in harsh environments under extreme corrosive circumstances.

Examples of ideal applications for Mita Flex FRP/GRP solutions:

• Oil and gas

• Wind energy

• Industry e.g. petrochemical,

• Water treatment

• Infrastructure e.g. tunnels

• Datacenters

• Fish farms

• Marine

Offshore wind, oil & gas and marine

Offshore applications offer a wide range of challenges, mainly due to heavy HV cabling in a high corrosive environment. With it's combination of the highly durable GRP materials and the flexibility of the MultiFlex Support System, Mita Flex is ideal for heavy duty applications like oil rigs and wind farms at sea.

Read more

Infrastructure

Installations in road tunnels, bridges or near railways can be challenging due to highly polluted air or moisture creating a highly corrosive environment. Mita Flex FRP/GRP materials are ideal for these applications and are available in four different resins to accommodate special requirements like fire performance and anti-static properties.

Read more

Agriculture and fish farming

Fish farms and animal stables that are cleaned with chemicals are both examples of highly corrosive environments that will be very challenging even for the most resistant of stainless steel alloys. GRP composites are highly corrosion resistant and also against UV light and most chemicals.

Heavy (chemical) industry

It's applications like water treatment, sulfuric acid plants plants and the petrochemical industry, where Mita Flex really excels. Our standard resin polyester class 1 (PC1) is commonly used as it offers great chemical resistance and durability. Additionally we have Vinylester (VE) resin available for excellent chemical resistance against most fuels, vapors and chemicals. For explosive environments we also have the AS anti-static resin, which contains carbon for increased conductivity.

Read more

Need support with your next project?

Our project sales team is here to help – contact us today.

What is FRP/GRP?

FRP/GRP refers to Glass fibre Reinforced Polymer, a man-made resin-based material, reinforced with glass fibre.

Polymer itself is extremely strong. It is a fiber material and in contrary to how it sounds it is very durable. It is resistant to most chemicals, stretching and shrinking, resistant to mildew and abrasion as well.

When it is reinforced with glass, it becomes a structural polymer. Further to these, GRP does not conduct heat. It has extra durability to adverse weather conditions and has UV stability which makes it an excellent candidate for outdoor applications, even for Wind substations built in the middle of the sea.

Long service life

→ UV-resistant

→ Corrosion resistance

→ High chemical resistance

→ Low maintenance

Fire resistance

→ Low thermal propagation

→ Halogen free

→ Self-extinguishing material

Materials

→ Strong and robust, yet flexible

→ Light weight

→ Available in 4 main resin types to

accommodate special requirements

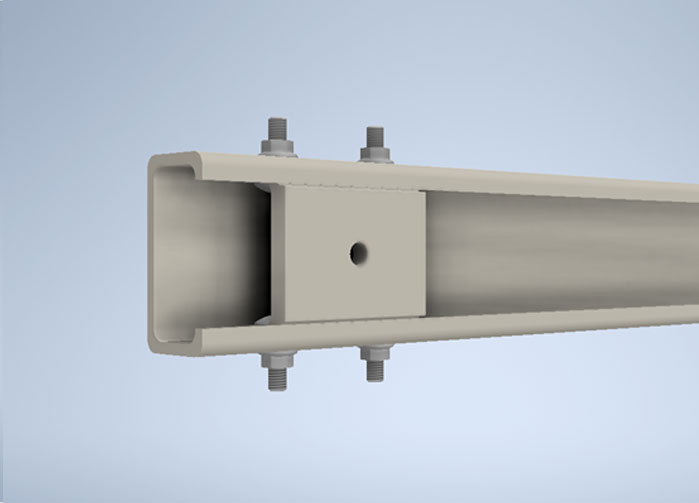

Introducing Our MultiFlex Support System

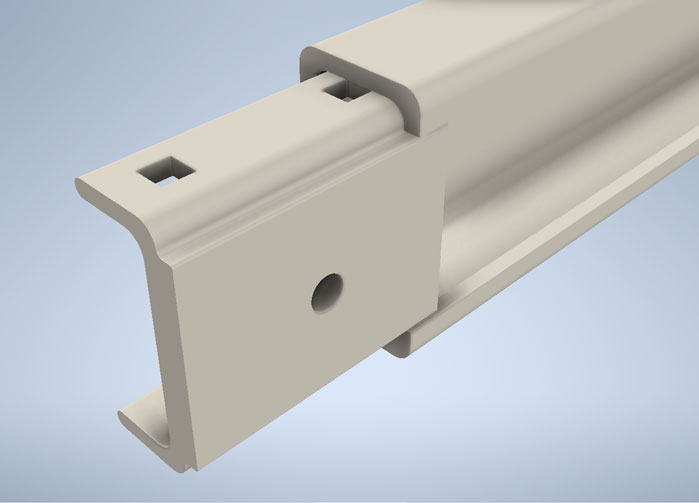

A versatile system of interchangeable parts that provides complete flexibility during installation and enables custom-made configurations. It is designed to support heavy cables and offers adjustment in every direction.

The system allows building a robust yet light framework by means of support channels and channel sleeves. The sleeve is inserted and fixed in the channel, and can then be combined with a wide variety of components such as angle brackets, flexi angle brackets and other components.

The system allows for full longitudinal and angular adjustability to position fixation points at exactly the right optimal position to fix cable cleats or other required materials.

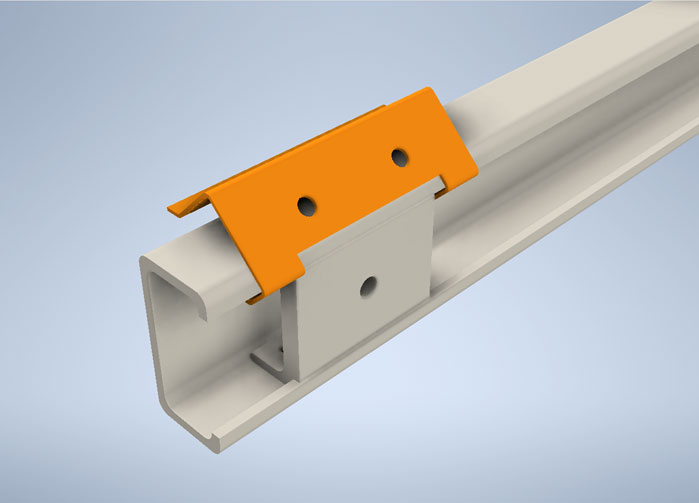

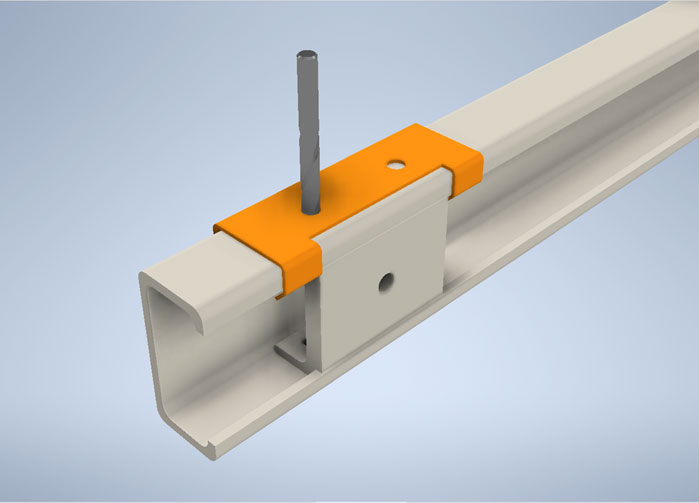

How does the MultiFlex system work?

Insert the sleeve into the channel.

Position the sleeve, and apply the drill jig.

Drill the required holes. One of the benefits of GRP is that it is easy to both cut and drill.

Insert the bolts and tighten the nuts. The sleeve can now be used for angle brackets, flexi angle brackets and other components.

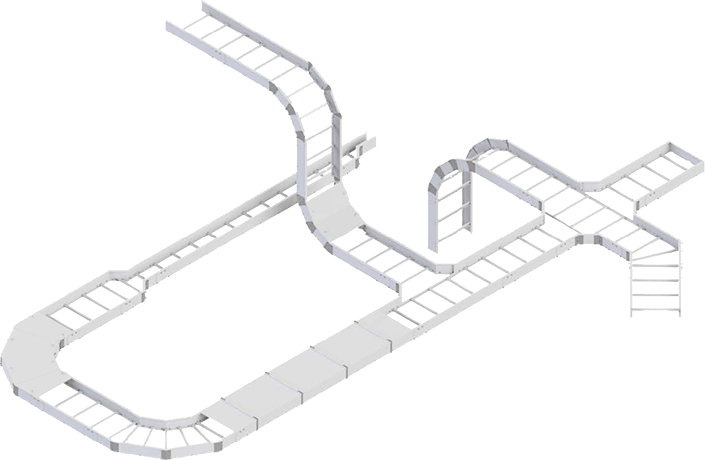

Cable Ladders

ladders, including fittings and accessories. Mita Flex cable ladders are available in three series:

→ LM100 (medium duty)

→ LMP150 (multi-purpose)

→ LH150 (heavy duty)

The FRP/GRP cable ladders are light, yet strong and corrosion-resistant. They are designed to deliver high performance, and maximum load capacity with reduced weight and improved handling, allowing easy and quick installation.

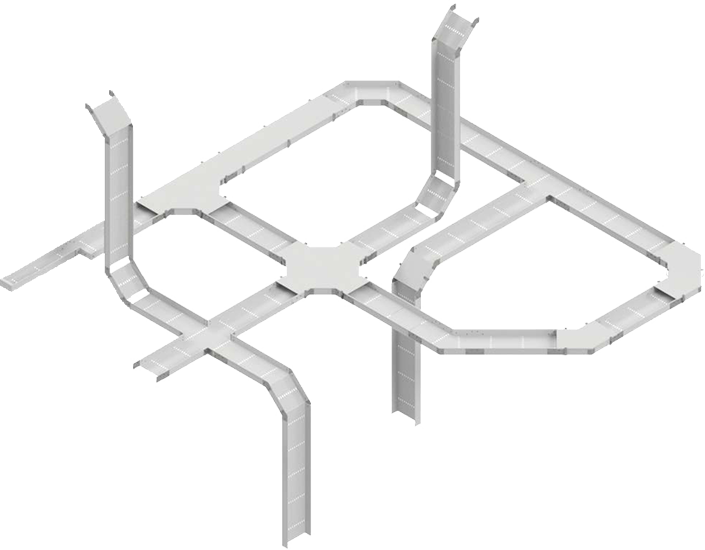

Cable Trays

Mita Flex offers a complete range of perforated composite cable trays, including fittings and accessories, available in two series:

→ CT50 Cable Tray(h 50 mm)

→ CT80 Cable Tray (h 80 mm)

The FRP/GRP cable trays are light, yet strong and corrosion-resistant.

Mita Flex FRP / GRP |

|||

|---|---|---|---|

| Mita Flex full system catalog | 15Mb | ||

| Mita Flex focus leaflet | 7Mb | ||

| Mita Flex installation manual | 8Mb |