Infrastructure

Infrastructure is a vital part of our daily life, and in all parts of the world the demand of efficient infrastructure to transport both people and goods in the most efficient manor is critical. All infrastructure projects are depending on electricity, for light and ventilation, but also for monitoring, alarms, fire detection etc. and for this you need a cable management system that is reliable in all situations to ensure the integrity of your infrastructure project.

Challenges

Most of the infrastructure projects are in more or less harsh environments; in road applications, you have the emissions from cars, and you may have special rock conditions or water coming into your tunnels. For a road bridge, it is quite normal to have cable management systems under the bridge used for light for the bridge, but also quite commonly used for utility purposes. Under bridges, there are in some occasions extremely harsh environment, specially in the Northern part of Europe, during wither they salt spray the roads, this salt will attach to the installation below the bridge, but due to the installation there are no rain that wash it away – and this may increase corrosion dramatically.

For railways, there are other challenges. Due to the electric trains and induced current all metallic parts need to be connected to earth, at least 25 meters to avoid galvanic corrosion. This is also something that needs to be maintained to ensure the integrity of the system.

Solutions

Road bridges

To avoid corrosion under bridges, the best solution is to use materials that will not corrode. All metallic materials, including stainless steel, will corrode under these circumstances, and our solution is the of GRP products.

Road Tunnels

There is a big variety when it comes to road tunnels, from simple tunnels where you have one cable ladder or tray going through the tunnel to big infrastructure projects where the complexity is huge. It also depends on where we are; in Nordic countries where it is common to use cable ladders, and in other parts of the world where cable trays are the common product to use. There are also relatively big differences in corrosion resistance needed; in dry inland environments, often HDG is sufficient, but in many cases, Stainless-steel or GRP is the right product. Wibe Group have created a wide range of products for all these applications, cable ladders and cable trays, support systems – in all material qualities

Railway applications

To avoid galvanic corrosion due to lack of earthing and bonding, the simplest and most cost-effective solution is to use non-conductive materials. Our GRP products are non-conductive, and there is no need for earthing and bonding. This will reduce the installation cost and will also reduce the maintenance cost during the whole lifetime of your installation. In normal conditions, GRPs have a lifetime expectancy of 50-75 years.

Mita-GMAX

Our newest invention when it comes to cable installation along railway tracks, this cable support system is an alternative to concrete ducts buried along the track. Mita-Gmax can be installed with a support distance of 6 meters, which gives a huge time saving compared to digging down concrete ducts.

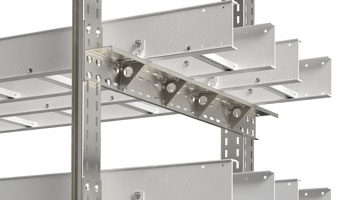

Mita Flex FRP/GRP Support System

A versatile system that provides complete flexibility.

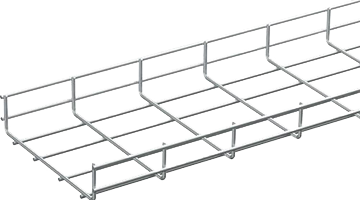

Defem Mesh Trays

Robust, easy-to-install mesh trays with impressive capacity and quality.

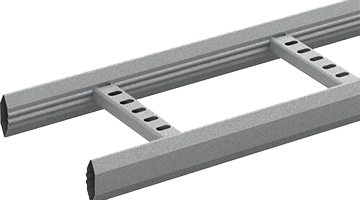

Wibe Cable Ladders

Robust and functional, enabling the same ladder to be used both horizontally and vertically.

GRP GMAX

Offers both posts and troughing in GRP, ensuring a lifetime performance with much less maintenance.

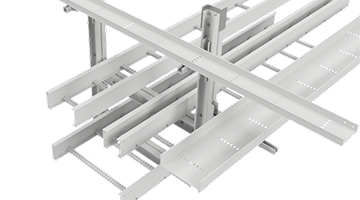

Wibe Flex support system

A flexible support system for all types of environments and disciplines

Need support with your energy or infrastructure project?

Our project sales team is here to help – contact us today.

Product range

Let's start our journey together

Every great project starts with a simple step—getting in touch. Whether you’re ready to start a project or need help calculating the details, we’re here to guide you every step of the way.

Need support with your energy or infrastructure project?

Our project sales team is here to help – contact us today.

Get in touch