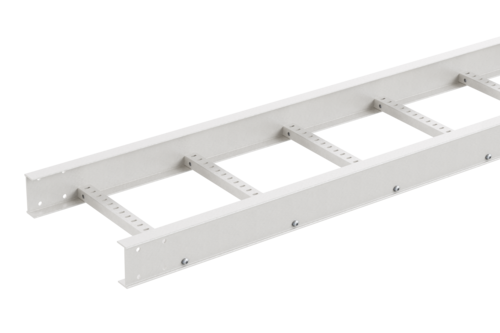

Cable ladder LM100 400 3m PC1

Item number

MLM1155PC1

Local code:

*

GTIN:

7321678028725

Description:

Cable ladder LM100 400 3m PC1

Properties

Status product

Product status

Commercialized

Commercial and Web

Short description

Cable ladder LM100 400 3m PC1

Medium description

Cable ladder LM100 400 3m PC1

Length

3000 mm

Width

418 mm

Height

100 mm

Material

GRP

Material type or surface treatment

PC1

Corrosion class

CX

Base

Activity

Cable support systems

Product family

Cable ladders

Brand

Mita

Range

Flex

GTIN

7321678028725

ETIM (EC000854-Cable ladder/wide span cable ladder)

Type of side joist (EF007666)

Profile (open)

Side wall perforation (EF001122)

No

Type of rung (EF001060)

Perforated profile

Fixation rung (EF008307)

Other

Height (EF000040)

100 mm

Width (EF000008)

400 mm

Length (EF001438)

3000 mm

Useful cross section (EF005140)

28400 mm²

Rung centre spacing (EF008185)

300 mm

Wide span model (EF006397)

*

Suitable for circuit integrity (EF007806)

No

Material (EF002169)

Plastic

Material quality (EF001257)

GRP (Glass fibre reinforced plastic)

Surface protection (EF000139)

Other

Colour (EF000007)

Grey

RAL (EF000116)

7047

Max. safe working load according to IEC 61537 (EF016305)

* N/m

Span between supports according to IEC 61537 (EF015363)

* mm

Load test type according to IEC 61537 (EF015362)

Type III

Weight (EF000167)

200 kg/m

Logistic

Customs code

39169010

Net weight

10.5 kg

Country of origin

Malaysia

Certification

ETIM class

EC000854

Product downloads

Manuals

Environmental Documents

Certificates

| Corrosion class | C1 | C2 | C3 | C4 | C5 | CX | |

| Environmental corrosion | Very low | Low | Average | High | Very high | Extreme | |

| Examples of environments | Indoors | Heated areas with arid atmosphere and insignificant quantities of pollutant, e.g. offices, shops, schools and hotels. | Non-heated areas with fluctuating levels of temperature and humidity. Few instances of condensation and low levels of airborne pollution, e.g. sports halls and warehouses. | Average levels of humidity and some airborne pollution resulting from production processes, e.g. breweries, dairies, laundries. | High humidity and considerable airborne pollution as the result of production processes, e.g. chemical plants, swimming pools and dockyards. | Buildings with almost permanent condensation and with high pollution | Industrial buildings with extreme humidity and aggressive atmosphere. |

| Outdoors | Atmospheres with low levels of airborne pollution. Rural areas. | Atmospheres containing some salt or average levels of air-borne pollution. Urban and light industrial areas. Areas affected by coastal conditions. | Atmospheres with average salt content or discernible levels of airborne pollution. Industrial and coastal areas. | Industrial areas with high humidity and aggressive atmosphere, and coastal areas with high salinity | Offshore areas with high salinity, industrial areas with extreme humidity, and aggressive atmospheres, sub-tropical or tropical atmospheres. | ||

|

Wibe Group designation

Exceeds requirements. Extremely high durability.

Recommended very high durability ( >20 years)

Possible alternative. High durability (10-20 years) |

Electro-galvanized (EG) |

|

|

||||

| Pre-galvanized (PG) |

|

|

|

||||

| Zinc+ (Z+) |

|

|

|

|

|||

| Hot-dip galvanized (HDG) |

|

|

|

|

|

||

| Zinkpox (ZP) |

|

|

|

|

|

|

|

| Stainless steel AISI 304L(SS304) |

|

|

|

|

|

|

|

| Stainless steel AISI 316L (SS316) |

|

|

|

|

|

|

|

| Glass Fibre Reinforced Polymer (FRP/GRP) |

|

|

|

|

|

|

|

This table shows estimated values.

For more detailed advice, please contact technical support at Wibe Group