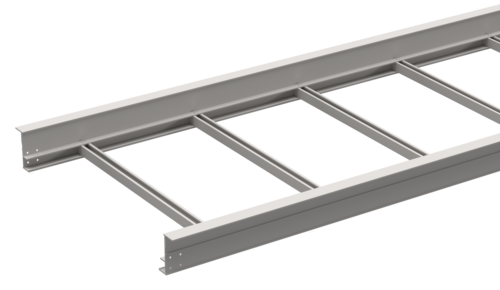

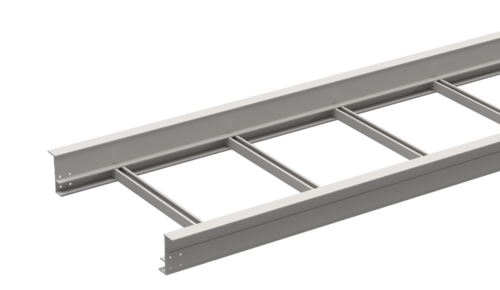

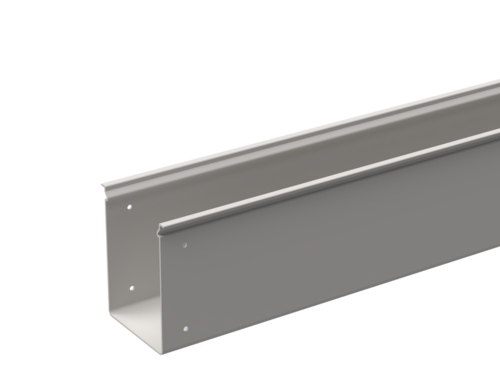

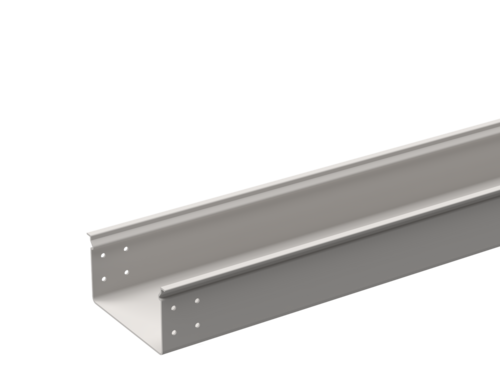

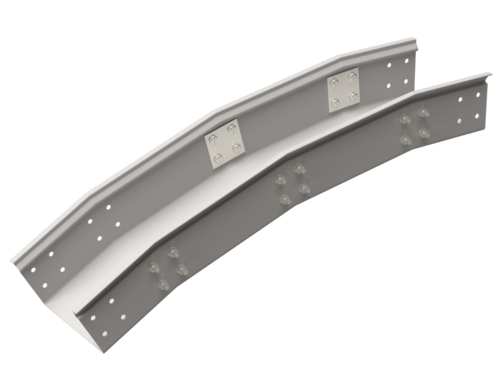

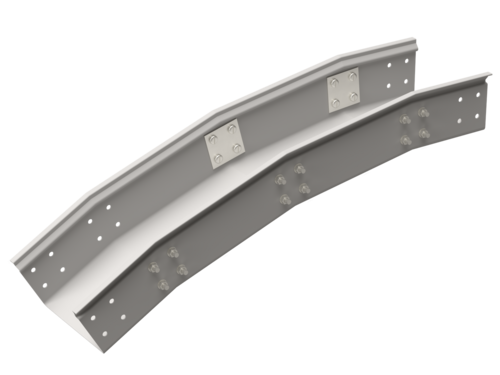

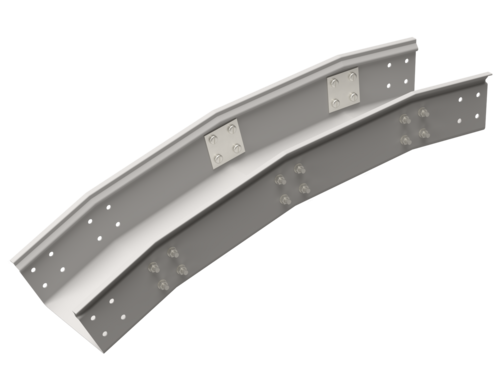

GXL Cable ladder 1000mm 3m PY1

GTIN: 7321678000288

| Corrosion class | C1 | C2 | C3 | C4 | C5 | CX | |

| Environmental corrosion | Very low | Low | Average | High | Very high | Extreme | |

| Examples of environments | Indoors | Heated areas with arid atmosphere and insignificant quantities of pollutant, e.g. offices, shops, schools and hotels. | Non-heated areas with fluctuating levels of temperature and humidity. Few instances of condensation and low levels of airborne pollution, e.g. sports halls and warehouses. | Average levels of humidity and some airborne pollution resulting from production processes, e.g. breweries, dairies, laundries. | High humidity and considerable airborne pollution as the result of production processes, e.g. chemical plants, swimming pools and dockyards. | Buildings with almost permanent condensation and with high pollution | Industrial buildings with extreme humidity and aggressive atmosphere. |

| Outdoors | Atmospheres with low levels of airborne pollution. Rural areas. | Atmospheres containing some salt or average levels of air-borne pollution. Urban and light industrial areas. Areas affected by coastal conditions. | Atmospheres with average salt content or discernible levels of airborne pollution. Industrial and coastal areas. | Industrial areas with high humidity and aggressive atmosphere, and coastal areas with high salinity | Offshore areas with high salinity, industrial areas with extreme humidity, and aggressive atmospheres, sub-tropical or tropical atmospheres. | ||

|

Wibe Group designation

Exceeds requirements. Extremely high durability.

Recommended very high durability ( >20 years)

Possible alternative. High durability (10-20 years) |

Electro-galvanized (EG) |

|

|

||||

| Pre-galvanized (PG) |

|

|

|

||||

| Zinc+ (Z+) |

|

|

|

|

|||

| Hot-dip galvanized (HDG) |

|

|

|

|

|

||

| Zinkpox (ZP) |

|

|

|

|

|

|

|

| Stainless steel AISI 304L(SS304) |

|

|

|

|

|

|

|

| Stainless steel AISI 316L (SS316) |

|

|

|

|

|

|

|

| Glass Fibre Reinforced Polymer (FRP/GRP) |

|

|

|

|

|

|

|

This table shows estimated values.

For more detailed advice, please contact technical support at Wibe Group