Wibe Flex is designed from the ground up to offer engineering, procurement, and construction contractors (EPCs,) specifiers and owners a cost efficient and future-proof support system for their installations.

Engineered design for easier and faster installation

What really sets Wibe Flex apart from other support solutions is the intelligent design of the entire system, down to each single part.

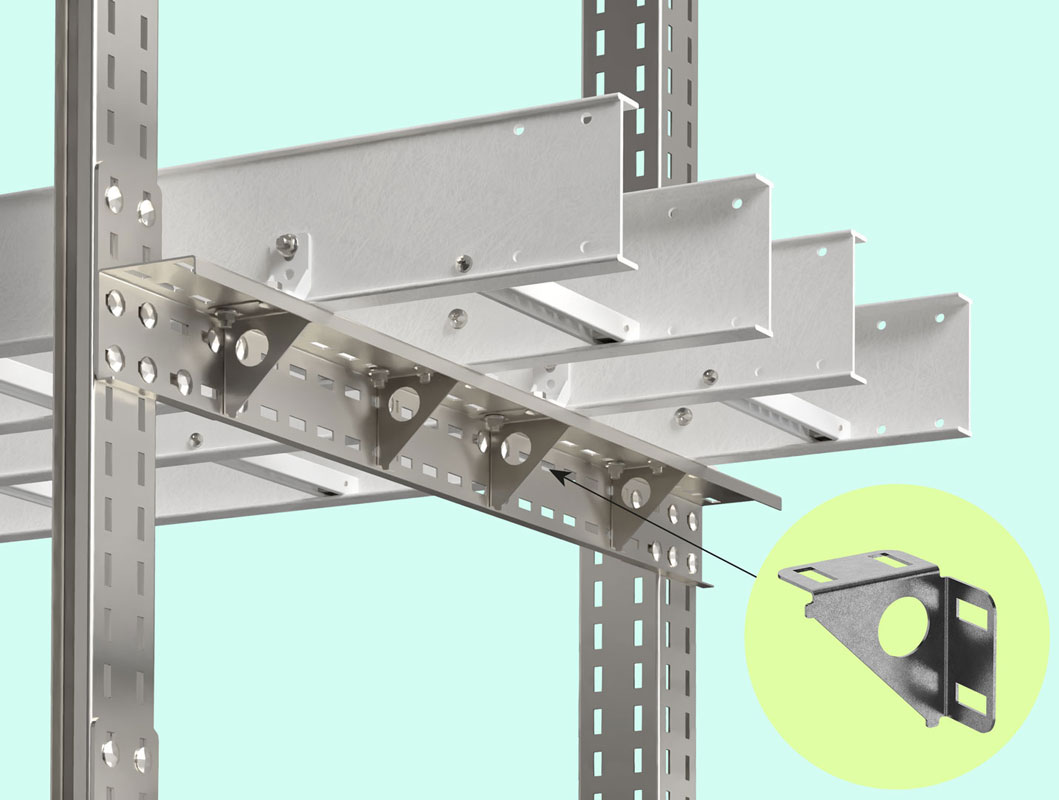

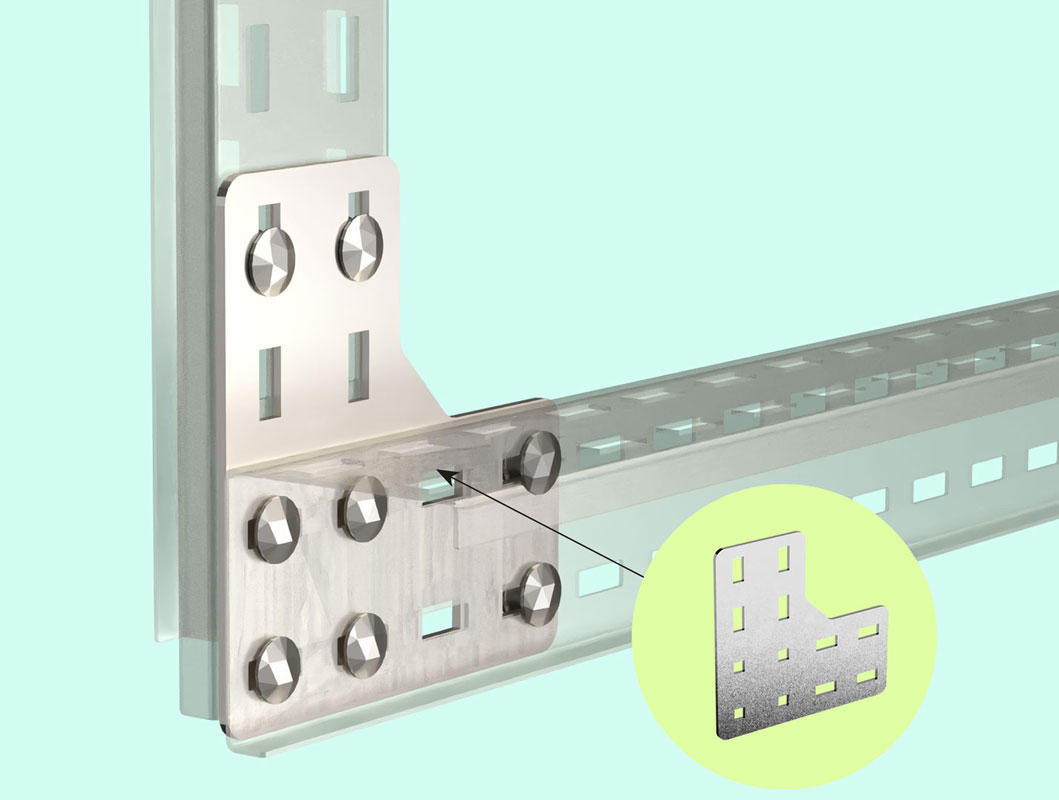

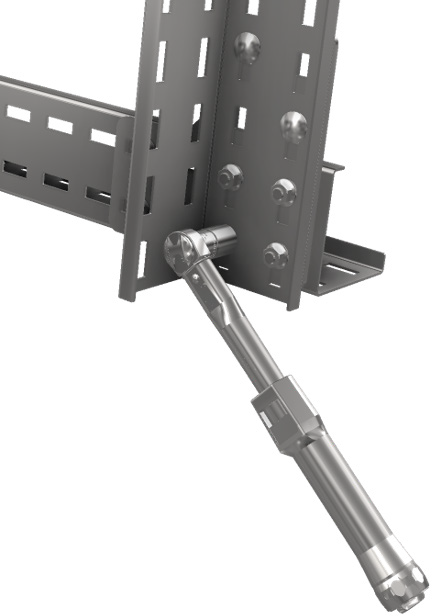

From the versatile profiles to vibration proof connections with locking bolts and flange nuts, a variety of easy-to-mount fixing brackets, and flexible bracing joints, Wibe Flex reduces cost and installation time without compromising on weight, load bearing capacity or torsion strength.

- •Profiles with open face design allows easier access for tools

- •Reduced fixings compared to typical strut applications

- •Self-locking bolts – apply torque from just one side

Excellent corrosion protection

Wibe Flex is available in stainless steel (AISI316L) suitable for use in environments up to corrosion class CX or hot-dip galvanised steel (HDG) recommended for use in environments up to corro-sion class C4

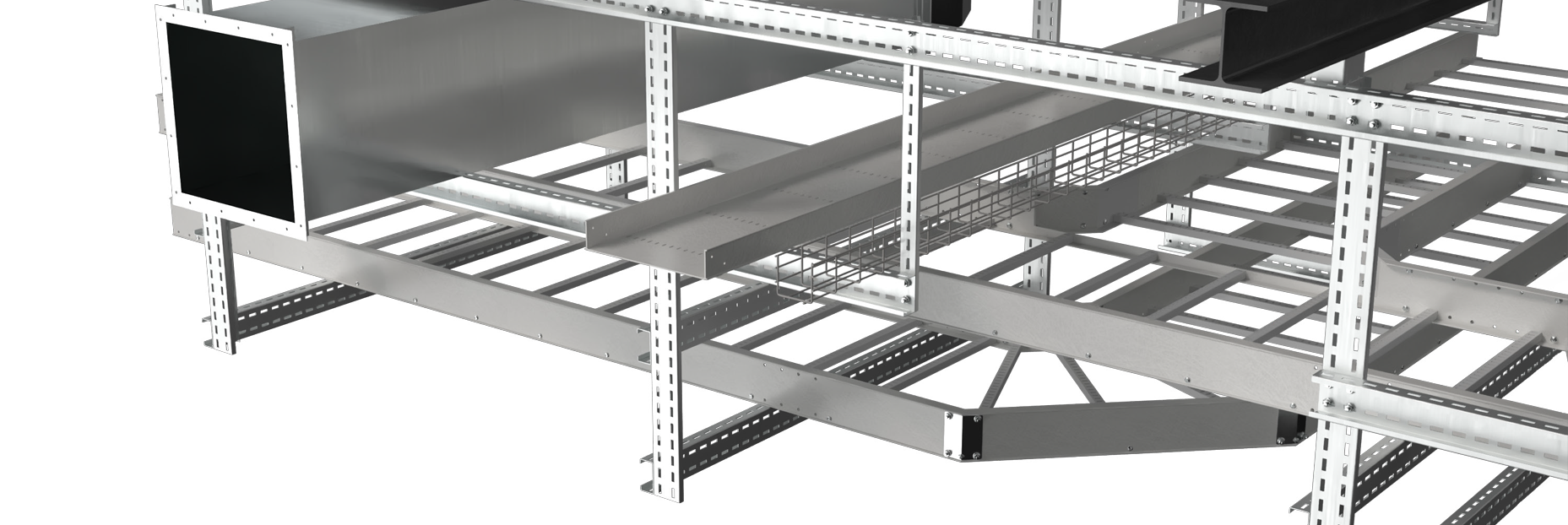

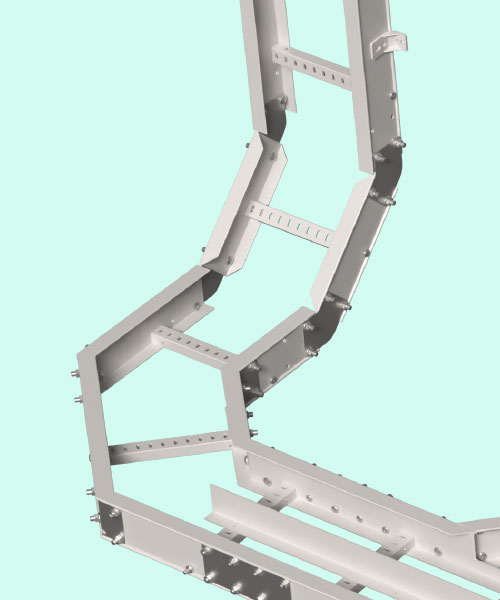

Building the Wibe Flex Grid system

The Wibe Flex Grid Installation concept facilitates the creation of a shared support structure for disciplines such as EI&T and HVAC. This approach establishes a fixed grid pattern of welded starter brackets, providing flexibility to accommodate both current and future installation requirements.

Wibe Flex profiles

PF50-2 (50x50mm)

Angled support profile. Available in 1.5 mm stainless steel and 2 mm HDG material thickness.

PF100-1 (100x50mm)

C-shaped support profile. Available in 2 mm stainless steel and 2.5 mm HDG material thickness.

PF100-2 (100x100mm)

Angled support profile. Available in 2 mm stainless steel and 2.5 mm HDG material thickness.

The Wibe Flex support system is based on three profiles. The open design of the profiles providing convenient access for tools and hands.

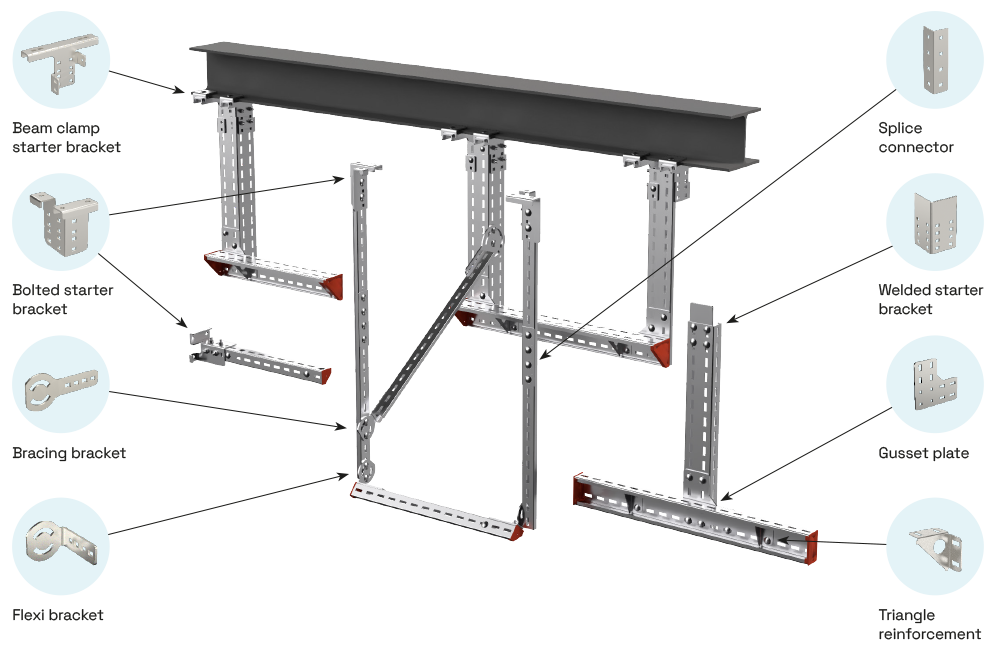

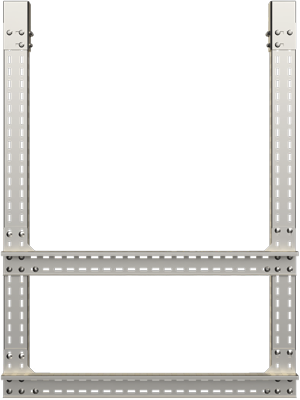

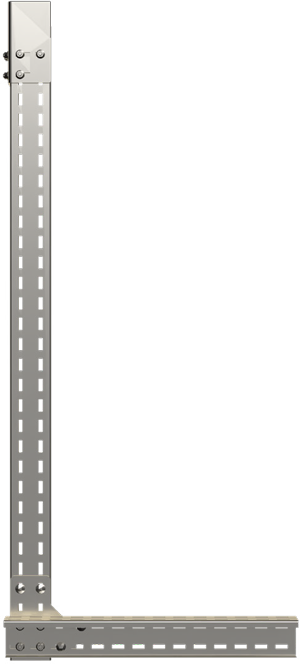

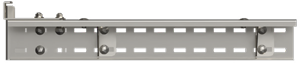

System overview

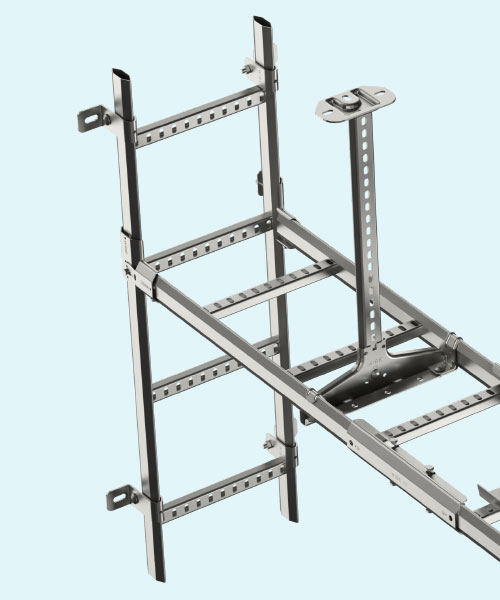

Typical standard supports

U-frame

T-frame

L-frame

Cantilever arm

The profiles can be bolted together to form U, T and L configurations as shown above. The load bearing capacity in these configurations can be further enhanced using combination with different accessories.

Ready to elevate your infrastructure?

Let’s talk about how Wibe Flex can support your next project

Gold level sustainability – built into every solution

Wibe Group was awarded the EcoVadis Gold Rating in 2025 which ranks the company in the top 1% of our industry worldwide. We commit to responsible sourcing, fair labor, and reducing environmental impact across the supply chain — because sustainable solutions matter as much as performance

Complete your installation

with Wibe Group’s cable management systems

Mita Flex GRP

Corrosion-resistant GRP/FRP cable management for harsh environments

Wibe cable ladders

Combines robust performance with ease of installation. Available in stainless steel and hot-dip galvanized steel

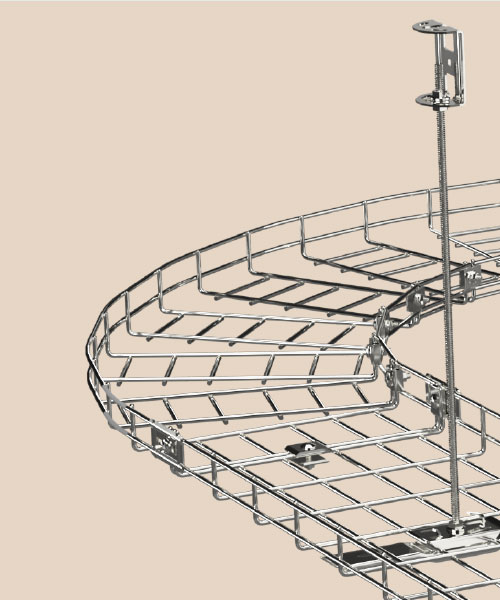

Defem mesh trays

Robust, flexible and versatile. Available in stainless and hot-dip galvanized steel.