Railway

Railway infrastructure demands reliable cable management to ensure smooth operation of critical systems like signaling, telecommunications, and power distribution. Our durable, weather-resistant solutions offer easy installation, supporting both modern and legacy railway networks effectively.

Challenges

Railway cable management faces distinct challenges due to harsh environmental conditions like extreme weather and constant vibration. Solutions must meet stringent safety regulations for fire resistance and emissions, ensuring system safety and reliability. Space constraints and integration with existing infrastructure demand compact, adaptable systems that allow easy maintenance access to minimize downtime. Additionally, future-proofing is essential, enabling seamless upgrades without costly infrastructure overhauls as railway technology advances.

Solutions

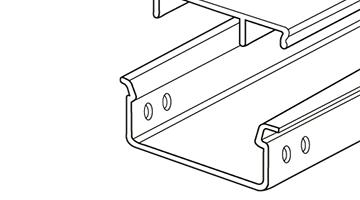

We provide a range of GRP cable support systems for rail applications, including cable ladders, trays/troughing, posts, and accessories, designed to meet the specific needs of the rail segment.

As a comprehensive manufacturer of corrosion-resistant industrial cable support products, Mita – powered by Wibe Group, has the solutions and expertise to specify a suitable solution, and deliver a product which can support any type of power circuit, cable, data and instrumentation.

Whether you are specifying a range of equipment for a major project or buying a selection of components for a simple maintenance installation, our premium range and support will put your mind at rest. Wherever you are situated and whatever you need, we are committed to meeting your requirements.

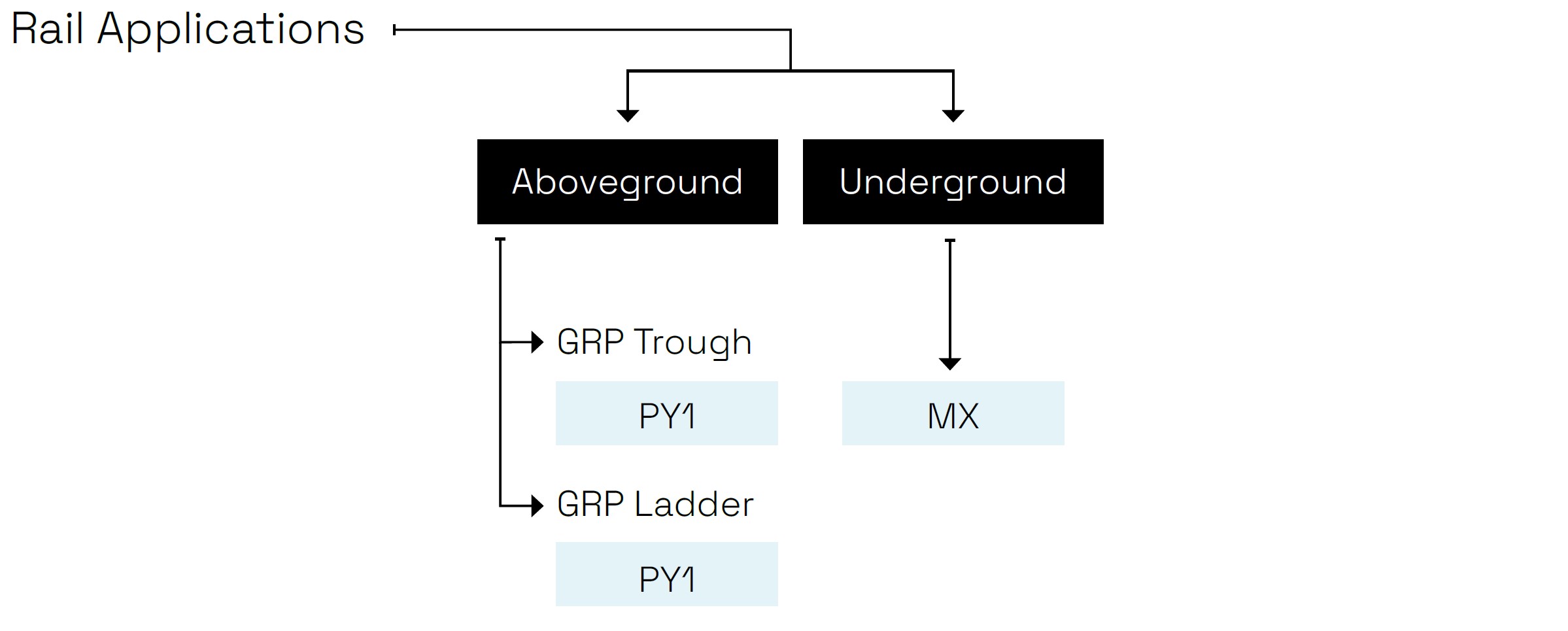

Resin types for railway applications

Mita offers two resin types suitable for railway:

Polyester Type 1 (PY1) has excellent fire retardance, which makes it suitable for railway, trackside or any other application requiring UL94 compliance and 5VA classification.

Modified Acrylic (MX) is great for any underground and tunnel application thanks to its BS6853 Smoke Emissions standard, and BS476-6 Fire Test compliance.

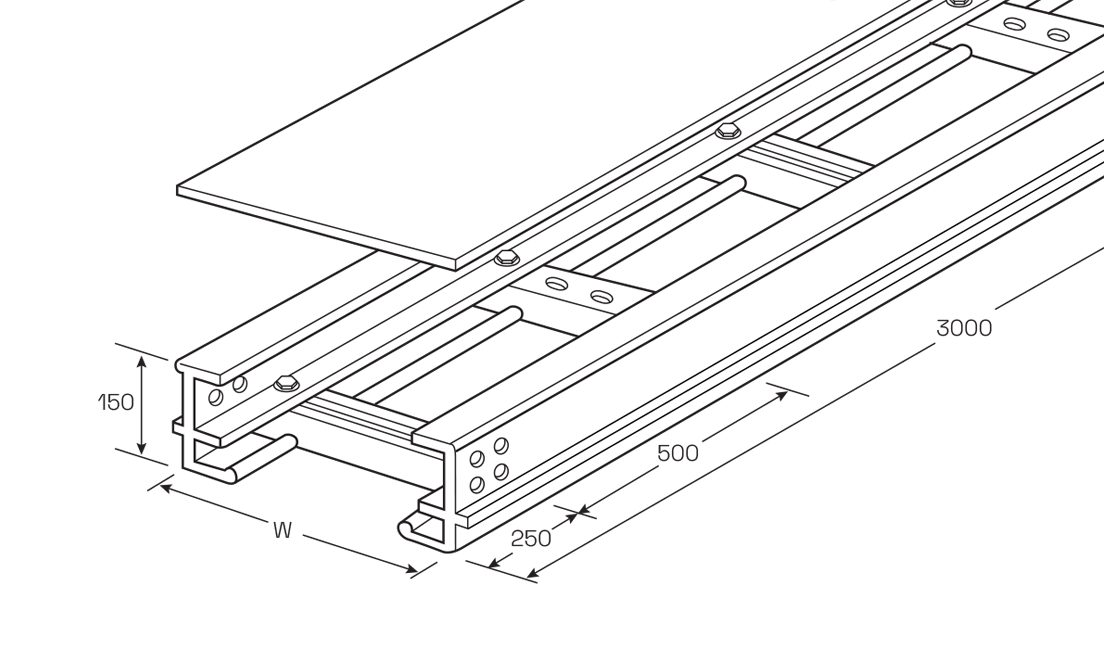

GRP GMAX

Offers both posts and troughing in GRP, ensuring a lifetime performance with much less maintenance.

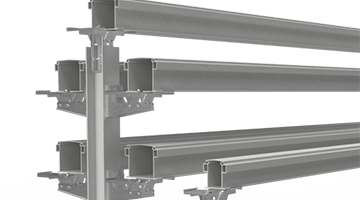

MultiFlex FRP/GRP Support System

A versatile system that provides complete flexibility.

CabSys® GRP Cable Trays

Available with a slotted or solid base, and clip-on cover.

Need support with your energy or infrastructure project?

Our project sales team is here to help – contact us today.

Why Mita GRP over Concrete or Steel?

-

-

Easy to install

-

- Reduced risk of staff injuries: GRP is easy to cut, lift and fit

-

- GRP is 70% lighter than steel

-

- Easier modifications with no need for painting, earth bonding or special tools

-

- Available in 3m or 6m lengths

-

-

Safe to use

-

- Mita GRP is RISQS certified

-

- GRP is non-conductive (=no earth bonding and no EMC liability).

-

- Slow heat transfer

-

- Halogen free

-

- Resistant to electromagnetic pulses.

-

- GRP offers excellent fire performance.

-

-

A lifetime performance

- GRP is UV resistant

-

- GRP is corrosion resistant, making it ideal for heavy duty environments with high air pollution and tough conditions.

-

- GRP means lower cost over time

-

-

Certified

- Mita and Wibe Group UK Ltd are RISQS certified

Wibe Group promise

We provide high-performance cable support systems for applications ranging from commercial buildings to extreme and demanding industrial or offshore environments. Our solutions are designed to meet the demands of all types of projects, ensuring durability and reliability tailored to each specific setting. We pride ourselves on providing the best customer service possible to our clients.

It has been part of the Wibe Group way of doing business since we started almost 100 years ago, and we are convinced that it will never go out of style.

EcoVadis Gold medal

In 2025, Wibe Group AB was awarded the EcoVadis Gold Medal in recognition of our sustainability efforts, placing us in the top 5% of all businesses worldwide and in the top 1% of companies within our industry. This accolade highlights our strong commitment to environmental impact, labour practices, ethics, and responsible sourcing, demonstrating excellence in sustainability and a transparent value chain.

| Mita | |||

|---|---|---|---|

| Mita solutions for rail applications | 15Mb | ||

| Mita GRP GMAX solution for rail applications | 3Mb |

Product range

Let's start our journey together

Every great project starts with a simple step—getting in touch. Whether you’re ready to start a project or need help calculating the details, we’re here to guide you every step of the way.

Need support with your energy or infrastructure project?

Our project sales team is here to help – contact us today.

Get in touch