ZIJKOPPELPLAAT 70 & 105 SZ

Artikelnummer

4561205

E-Nummer:

*

GTIN:

8428031039042

Omschrijving:

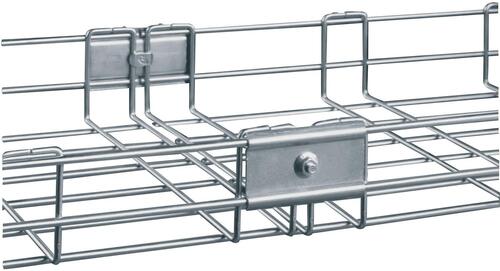

ZIJKOPPELPLAAT 70 & 105 SZ

Wibe Group. 4561205 - Stago - Performa - zijkoppelplaat - 70/105mm - 46/-/80mm - elektrolytisch verzinkt

Eigenschappen

Status Product

Product status

Gecommercialiseerd

Product Omschrijving

Korte omschrijving

ZIJKOPPELPLAAT 70 & 105 SZ

Medium omschrijving

Performa - Zijkoppelplaat - 70/105mm - 46/-/80mm - Elektrolytisch verzinkt

Materiaal

Staal

Materiaaltype of oppervlaktebehandeling

Electrolytisch verzinkt

Corrosieclassificatie

C1

Basis

Activiteit

Kabeldraagsystemen

Productfamilie

Draadgoten

Merk

Stago

Serie

Performa

GTIN

8428031039042

ETIM (EC002413-Verbindingsstuk kabeldraagsysteem)

Uitvoering (EF000010)

Langsverbinder

Scharnierende verbinder horizontaal (EF006392)

Nee

Scharnierende verbinder verticaal (EF006393)

Nee

Verbindingswijze (EF000064)

Schroefverbinder

Geschikt voor draadgoot (EF005163)

Ja

Geschikt voor kabelladder (EF005165)

Nee

Geschikt voor kabelgoot (EF005166)

Nee

Geschikt voor kabeldraagsysteembreedte (EF008339)

60-600 mm

Geschikt voor kabeldraagsysteemhoogte (EF006391)

105 mm

Geschikt voor draadgootdraad (EF005164)

3.9-4.9 mm

Lengte (EF001438)

* mm

Geschikt voor functiebehoud (EF007806)

Nee

Materiaal (EF002169)

Staal

Roestvaststaal (RVS), gebeitst (EF006388)

Nee

Kwaliteitsklasse (EF001257)

Overig

Oppervlaktebescherming (EF000139)

Elektrolytisch verzinkt

Kleur (EF000007)

*

RAL (EF000116)

*

Logistiek

Gewicht verpakking 1

0,078 kg

Lengte verpakking 1

80 mm

Breedte verpakking 1

46 mm

Hoogte verpakking 1

6 mm

Douane code

73269098

Netto gewicht

0,08 kg

Land van productie

NL

Certificering

ETIM classificatie

EC002413

Duurzaamheid

GWP Total A1-A3

0,16926 kgCO2e

Product downloads

| Corrosie klasse | C1 | C2 | C3 | C4 | C5 | CX | |

| Omgevingscorrosie | Zeer laag | Laag | Average | Gemiddeld | Zeer hoog | Extreem | |

| Voorbeelden van omgevingen | Binnenshuis | Verwarmde ruimtes met een droge atmosfeer en verwaarloosbare hoeveelheden vervuilende stoffen, zoals kantoren, winkels, scholen en hotels. | Niet-verwarmde ruimtes met wisselende temperatuur en luchtvochtigheid. Weinig condensvorming en lage niveaus van luchtvervuiling, bijvoorbeeld sporthallen en magazijnen. | Gemiddelde luchtvochtigheid en enige luchtvervuiling als gevolg van productieprocessen, bijvoorbeeld in brouwerijen, zuivelbedrijven en wasserijen. | Hoge luchtvochtigheid en aanzienlijke luchtvervuiling als gevolg van productieprocessen, bijvoorbeeld in chemische fabrieken, zwembaden en scheepswerven. | Gebouwen met vrijwel permanente condensatie en een hoge mate van vervuiling. | Industriële gebouwen met extreme luchtvochtigheid en een agressieve atmosfeer. |

| Buiten | Atmosferen met een lage concentratie luchtvervuiling. Landelijke gebieden. | Atmosferen met een bepaalde hoeveelheid zout of een gemiddelde concentratie luchtvervuiling. Stedelijke gebieden en lichte industriegebieden. Gebieden die beïnvloed worden door kustomstandigheden. | Atmosferen met een gemiddeld zoutgehalte of waarneembare niveaus van luchtvervuiling. Industriële en kustgebieden. | Industriële gebieden met een hoge luchtvochtigheid en een agressieve atmosfeer, en kustgebieden met een hoog zoutgehalte. | Offshoregebieden met een hoog zoutgehalte, industriële gebieden met extreme luchtvochtigheid en agressieve atmosferen, subtropische of tropische atmosferen. | ||

|

Wibe Group-aanduiding

Voldoet ruimschoots aan de eisen. Uiterst duurzaam.

Aanbevolen zeer hoge duurzaamheid (>20 jaar)

Mogelijk alternatief. Hoge duurzaamheid (10-20 jaar). |

Elektrolytisch verzinkt (EG) |

|

|

||||

| Voorgegalvaniseerd (PG) |

|

|

|

||||

| Zink+ (Z+) |

|

|

|

|

|||

| Thermisch verzinkt (HDG) |

|

|

|

|

|

||

| Zinkpokken (ZP) |

|

|

|

|

|

|

|

| Roestvrij staal AISI 304L (SS304) |

|

|

|

|

|

|

|

| Roestvrij staal AISI 316L (SS316) |

|

|

|

|

|

|

|

| Glasvezelversterkt polymeer (FRP/GRP) |

|

|

|

|

|

|

|

Deze tabel toont geschatte waarden.

Voor meer gedetailleerd advies kunt u contact opnemen met de technische ondersteuning van Wibe Group.